Tesla’s Technology Cuts Car Manufacturing Costs by 40%

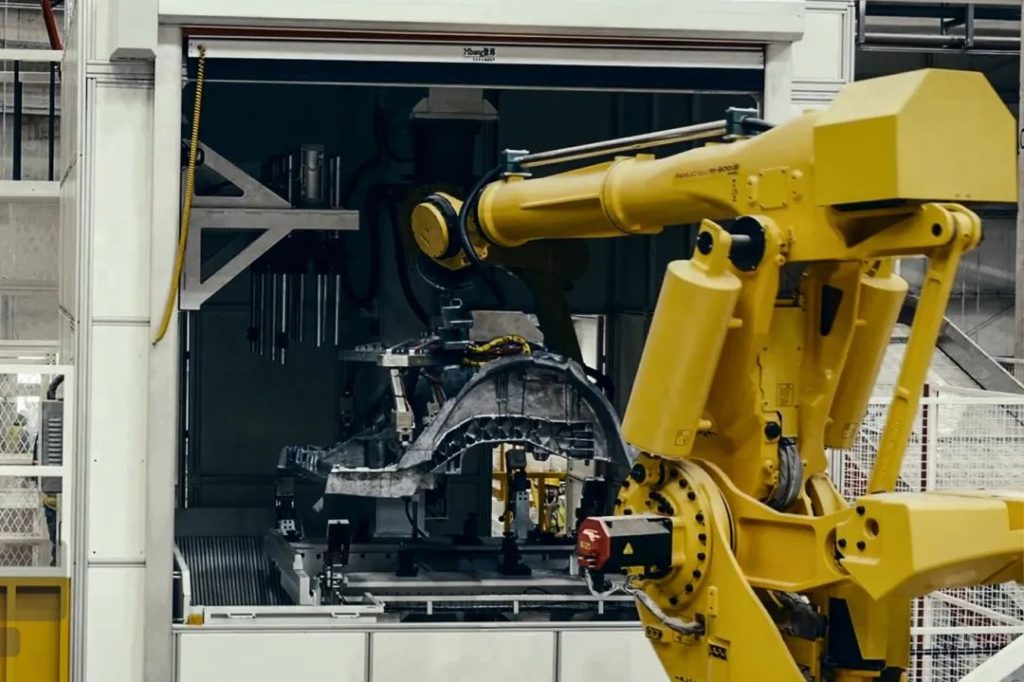

What is Integrated Die-Casting?Integrated die-casting technology was first introduced by Tesla in 2019 and applied to the production of the Model Y’s rear floorboard in 2020. Soon after, the concept of integrated die-casting gained widespread attention in the market. New energy vehicle companies such as NIO and XPeng, as well as traditional automakers like Volvo, Volkswagen, Audi, and Mercedes-Benz, began to explore the integration of die-casting technology in their vehicle bodies and floorboards.Integrated die-casting refers to the integration of vehicle body parts. In the traditional design, multiple small, separate parts are combined, but after reengineering, they are highly integrated into a single, large part. This process uses large die-casting machines to form the part in one step, eliminating the welding process. The result is a complete large component with advantages such as simplified processes, higher production efficiency, and greater lightweight potential, which significantly reduces manufacturing costs. Integrated die-casting replaces the multiple steps of assembly and welding with a single die-casting step, reducing both part costs and assembly costs.

The integrated die-casting technology is derived from automotive sheet metal casting, and it’s more of a shift in thinking than a purely innovative technology. The core idea involves rethinking traditional molds by reversing the mold’s internal core design into an external core and replacing common plastic injection molding techniques with metal materials.Today, die-casting is widely used in automotive parts. However, there’s a key difference between traditional die-casting and integrated die-casting. Traditional die-casting involves using a die-casting machine to mold metal into a desired shape, where the metal is heated to a point where it can change shape. In contrast, integrated die-casting directly injects molten metal into a mold to form a single, final part.Tesla is the first company to apply this die-casting technology to the vehicle’s white body sheet metal. While many automakers use die-casting for larger components, no one had previously considered using it for thin sheet metal areas. Tesla, however, took the bold step to apply this technique to the body shell on a large scale.

Cost Reduction Through Integrated Die-Casting.In the context of the carbon-neutral push, lightweighting has become a major trend in the automotive industry. Integrated die-casting plays a significant role in achieving this goal. For example, the use of integrated die-casting in the Model Y’s rear floorboard assembly has reduced its weight by 30%. Compared to existing manufacturing processes, integrated die-casting improves production efficiency by simplifying production steps and enhancing the assembly speed.Most importantly, the application of integrated die-casting technology reduces costs across various areas such as production, land use, and labor. For Tesla, the production cost of the Model Y has decreased by 40%. This reduction is visible in the published data, demonstrating how integrated die-casting impacts the overall vehicle cost.But how exactly does this cost reduction occur? Firstly, integrated die-casting consolidates several smaller parts into a single component, cutting down on outsourcing and the associated costs of producing individual parts. In traditional methods, different suppliers produce individual parts, which are then assembled by the automaker. Integrated die-casting eliminates this process, reducing part costs significantly.

Secondly, integrated die-casting reduces the investment in the welding line. Since integrated die-casting eliminates the need for a welding assembly line, it saves on construction and labor costs, as well as on floor space.Finally, integrated die-casting reduces the costs of vehicle design and development. Traditionally, analyzing and designing welded sheet metal components takes a lot of time, both for structural analysis and design iterations. With integrated die-casting, the entire component can be analyzed as one unit using finite element analysis (FEA). This process is much quicker than analyzing the multiple components in traditional sheet metal design. Moreover, the design of die-cast parts is more parametric, meaning that a new part can be designed by simply altering a few key dimensions, greatly reducing development time and costs.These savings have a significant impact on the overall cost of the vehicle. From a results-oriented perspective, cost reduction is inevitable when using integrated die-casting.Impact on the Next Round of Competition.Integrated die-casting will play a crucial role in the next phase of automotive competition, with two primary areas of focus: delivery speed and new model development cycles, and cost competition.

In terms of delivery speed and new model development cycles, integrated die-casting primarily improves development cycle costs. Once an automaker establishes its own die-casting production line, the only change required to produce parts for a new model is replacing the mold cores. These mold cores can be made much faster than traditional stamping or welding dies. This allows for rapid prototyping and faster delivery of new models, significantly boosting the automaker’s competitiveness.As for cost competition, integrated die-casting will be increasingly applied to white-body manufacturing. Once a die-casting production line is established, automakers will be able to produce more parts using die-casting. In addition to the widely adopted rear wheel housings and rear seatbacks, die-casting will extend to other components such as door inner panels, floorboards, front cross beams, and engine compartment assemblies. These areas represent key cost-reduction opportunities for integrated die-casting technology.While some might argue that these are predictions, it’s clear that price is one of the most important factors when satisfying consumer demands. Cost-effectiveness remains a primary consideration in the market. Therefore, the future competitive focus of integrated die-casting will center on reducing product costs and accelerating the launch of new models.

Will Domestic Automakers Adopt Integrated Die-Casting?Whether domestic automakers will adopt integrated die-casting technology depends on their current technical capabilities. Geely, for example, has already adopted this die-casting technology, demonstrating that domestic automakers are exploring its application. However, not all automakers are suited to implement this technology, as die-casting of white-body sheet metal assemblies requires a high level of technical expertise.From design analysis to production line planning, material supply, and significant capital investment, introducing this technology requires careful consideration. While China’s automotive supply chain is mature, automakers must evaluate whether it is worthwhile to enter this new field. Implementing integrated die-casting will not only require overcoming technological and financial challenges but also involves restructuring the supply chain—an enormous undertaking.If automakers are to adopt integrated die-casting, they need to consider several factors.Technical Feasibility: While integrated die-casting does not fundamentally change the production process, the technology is not as simple as it seems. The key issue isn’t just the design of the components; rather, it’s whether the company has the right experts in aerodynamics, fluid mechanics, and thermodynamics. Unlike smaller die-casting parts, white-body parts are large and thin, and issues such as material performance in terms of strength and toughness must be carefully considered.

The metal used for integrated die-casting must have sufficient strength and flexibility—not too brittle or too hard.Additionally, automakers need to evaluate the appropriate metal alloy compositions and ensure that their die-casting machine suppliers meet these requirements. The current energy-efficient and carbon-reducing policies also raise the question of whether die-casting machines can meet low-carbon, high-efficiency standards. And, of course, the automaker must be willing and able to make a significant financial investment in the technology.Factory Challenges: Most automakers rely on external suppliers for die-casting components, meaning their current factories do not require additional workshops or equipment. However, integrating die-casting is a high-investment project, and the automaker will need to plan and procure its own die-casting production line. This is not just about purchasing a single die-casting machine; it involves setting up a complete production line. The automaker will need to assess whether its current facilities can accommodate the additional equipment, such as melting furnaces, die-casting machines, and auxiliary equipment. If not, new facilities and a redesigned logistics system may be required.

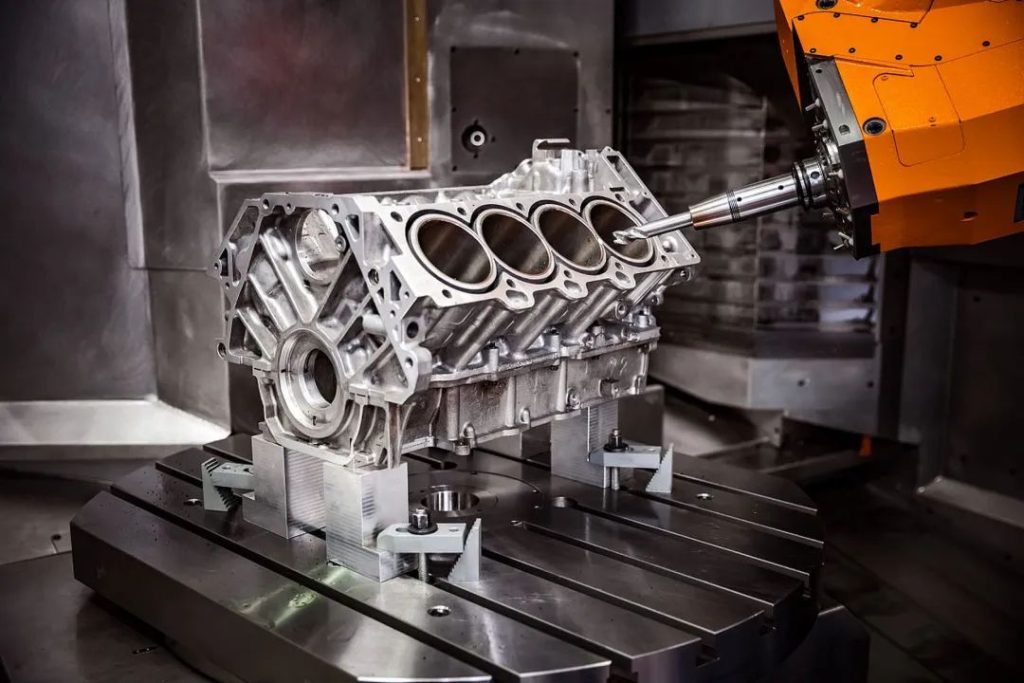

Changes in Production Processes.While integrated die-casting reduces the workload in the welding shop, it also increases processing steps. Vehicle manufacturing doesn’t only involve welding. The integrated die-casting parts need to be connected and fixed to other components, and external decorations must also be attached to these die-cast parts. Therefore, these die-cast parts must undergo further processing after they are cast, such as milling, drilling, tapping, and inserting nuts and bolts. The machinery used for processing these parts is an added step in the production process. After the die-casting line, a machining line is added to perform secondary processing on the die-cast components to meet subsequent requirements. So, it’s important not only to look at what integrated die-casting saves, but also to consider what it adds to the process.Impact on Consumers.The advantages of integrated die-casting technology in reducing costs and shortening delivery cycles will inevitably have a significant impact on end consumers.

Overall, for consumers, there are four main impacts:Lightweighting reduces energy consumption: A lighter vehicle body means lower energy consumption. For electric vehicles, this translates into better energy efficiency, while for gasoline vehicles, it leads to fuel savings.Cost reduction: Integrated die-casting reduces manufacturing costs, which can, in turn, lower the purchase price for consumers. Once die-casting technology is fully implemented and running smoothly in a car manufacturer’s production line, the overall manufacturing cost will decrease. This, in turn, reduces the cost of individual parts, leading to lower overall vehicle costs. This allows car manufacturers to maintain their expected profit margins while also offering greater pricing flexibility in a competitive market.Faster product availability: Integrated die-casting can significantly reduce the time required for model development and shorten delivery times.

As consumer demand for new models and personalized vehicles increases, integrated die-casting technology will help manufacturers meet these needs by speeding up product development and improving delivery speed.Increased maintenance and insurance costs, and potential reduction in overall vehicle strength: First, let’s address the increased maintenance costs. Integrated die-casting means that what used to be hundreds of parts is now a single piece. If a car is damaged and the integrated die-cast part is affected, the possibility of repairing that part is almost zero. Once an integrated die-cast part is damaged, it loses its basic functionality, and even a minor collision could require replacing the entire part. In contrast, in traditional welded vehicles, even if a part is damaged, it can often be repaired locally or replaced with a few parts at a much lower cost. With integrated die-casting, however, the entire part needs to be replaced, which could incur significant costs in both removal and reinstallation.

Next, there’s the increase in insurance premiums. Although insurance companies currently don’t treat cars with integrated die-casting bodies differently, as this technology becomes more widespread and issues with die-cast parts arise more frequently, insurers will inevitably recognize the higher risk associated with these vehicles. This could lead to higher premiums for cars using integrated die-cast components.Lastly, impact on overall vehicle strength. The vehicle body is an integrated whole that’s assembled and welded in the production line, ensuring the strength of the vehicle structure. However, when a die-cast part needs to be replaced due to damage, it can compromise the overall strength of the vehicle. In traditional vehicles, welded components maintain their integrity because each part is designed to be installed sequentially, following safety and collision requirements. But when a die-cast part fails and needs replacement, removing the damaged part and installing a new one may reduce the vehicle’s structural strength. Unless all manufacturers using die-cast parts install them as the final step in the production process, any replacement of die-cast components could potentially weaken the overall vehicle structure.

Opportunities and Challenges for Domestic Automakers.Integrated die-casting technology offers many advantages, but it also presents inevitable disadvantages. No technology is perfect, and for domestic automakers, integrated die-casting represents both an opportunity and a challenge. Even if the technology isn’t yet feasible, automakers can gradually implement it in smaller areas, and eventually gain a competitive edge in the future market.The key to successfully adopting integrated die-casting lies in the willingness to invest in new production capabilities and to adapt existing facilities. While some domestic car manufacturers, like Geely, have already integrated die-casting technology into their production lines, others may still face challenges in doing so. From design analysis to supply chain management and substantial financial investment, introducing this technology requires careful consideration.Despite the challenges, it’s clear that integrated die-casting could significantly alter the landscape of automotive manufacturing, particularly as it allows for quicker model development and more cost-effective production. Those who are able to adapt early will be in a stronger position in the competitive market.